Products

Dental Air Plant

- All MMPL Dental Air Plants conform to the European Pharmacopoeia Standard which defines the quality of Dental Air is dry clean and bacteria free.

- European Pharmacopoeia Standard Content of Dental air

- Oxygen 20.9 ± 0.5%

- Nitrogen 78.0% by inference

- Carbon dioxide <500 ppm v/v

- Carbon monoxide <5 ppm v/v

- Oil <0.1 mg/m3

- Water < 1032 vpm (DPt –20ºC at atm p)

- Particulate Free from visible particles in a 75-litre sample (taken at 150 litres/min)

- Sulphur dioxide <1 ppm v/v

- Nitric oxide + nitrogen dioxide <2 ppm v/v

Key Features

- Fully compliant to HTM2022 Specification

- Compressors can be supplied oil lubricated or oil free type

- Flexible connections and anti-vibration mounts on all compressors

- Fail safe start up control system in the event of power loss

- Alarm and BMS Outputs for remote status indication

- All Plants tested and certified before dispatch

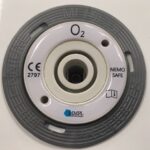

Medical Gas Terminal Units Nemo Safe

-

- O2 (Oxygen)

- N20 (Nitrous Oxide)

- ENT (Entonox)

- AIR (Medical Air)

- AIR-800 (Surgical Air)

- VAC (Vacuum)

- AGSS (Anaesthetic Gas Scavenging System)

- CO2 (Carbon Dioxide)

- N2 (Nitrogen)

Key Features

- Compact and aesthetically designed.

- 1st fix includes copper stub for ease of installation.

- Plaster shield available for flush installations.

- All 1st T.U.s are supplied with blank plug for Pipe- work 1st fix pressure testing.

- Each component indexed to ensure gas specificity is maintained.

- Quality robust materials of construction.

- Each Terminal Unit is fully tested prior to despatch.

- Proven reliability.

Medical Gas Terminal Unit Nemo XP

-

- O2 (Oxygen)

- N20 (Nitrous Oxide)

- ENT (Entonox

- AIR (Medical Air)

- AIR-800 (Surgical Air)

- VAC (Vacuum)

- AGSS (Anaesthetic Gas Scavenging System)

- CO2 (Carbon Dioxide)

- N2 (Nitrogen)

Key Features

- Compact and aesthetically designed,

- 1st fix includes copper stub for ease of installation,

- Plaster shield available for flush installations,

- Terminal Unit first fix is supplied with blank plug to enable pipework pressure testing ,

- Each component indexed to ensure gas specificity is maintained,

- Quality robust materials of construction,

- Each Terminal Unit is fully tested prior to despatch,

- Proven reliability,

Standard Specification

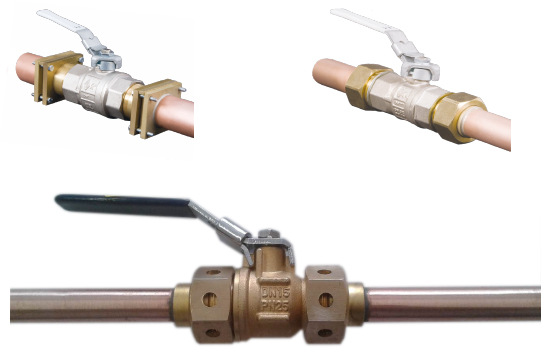

Degreased Lockable Line Valves

Key Features

- Fully HTM 02-01 compliant

- Tamper proof locking mechanism that is lockable in both open and closed positions

- Can be supplied for use with pipework of 15mm to 159mm

- All valves fitted with flat faced 'o' ring unions

- Every unit is tested for pressure and tightness before dispatch

NIST Lockable Line Valves

Key Features

- Complies fully with all relevent standards

- Fitted with BS 739 NIST connectors

- Sealed shut off NIST valves

- Uses flat faced ‘o’ ring pipeline unions

- Fitted with a lockable Handle

- Lockable in both open and closed positions

- Pressure tested prior to despatch

- Tested for tightness prior to despatch

- 12 month warranty

- Each NIST valve is supplied with blanking facility

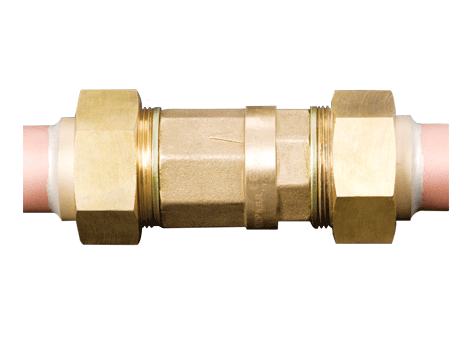

Non-Return Valves

Key Features

- Fully HTM 02-01 compliant

- Can be supplied for use with pipework of 15mm to 76mm

- Fitted with flat faced 'o' ring unions

- Every unit is tested for pressure and tightness before dispatch

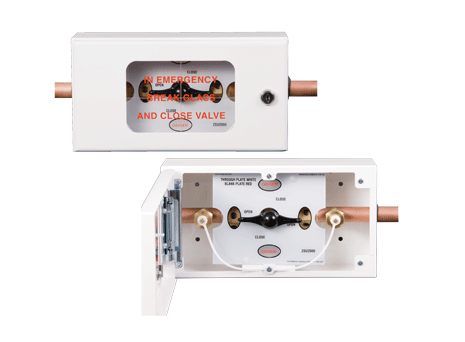

AVSU

Key Features

- Fully HTM 02-01 compliant

- Fitted with BS 739 NIST connectors

- Fitted with unique laser grooved "Safe Break" window

- Fully removable door for easy access

- Can be supplied for use with pipework of 22mm 54mm

- All valves fitted with flat faced 'o' ring unions

Options

- Flush Surrounds

- Pressure Switches

- Disposable Plaster Shield

- Top or Side Entry Pipework

- Suited Key Locks

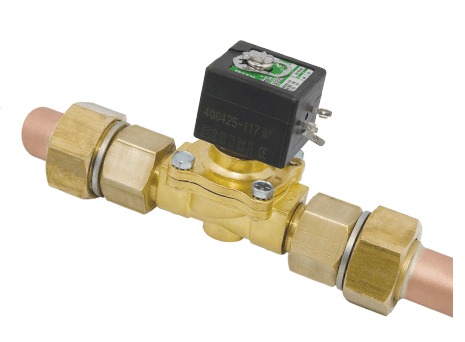

Solenoid Valves

Millennium Medical Products Limited produces and supplies a full range of Solenoid Line Valves.

All Solenoid Valves are factory tested for pressure prior to dispatch and come with a comprehensive warranty.

Key Features

- Electrically operated solenoid valve - various working voltages available

- Available in Normally Open and Normally Closed variants

- Can be supplied for use with pipework of 15mm to 54mm

- All valves fitted with flat faced 'o' ring unions

- Every unit is tested for pressure and tightness before dispatch

Medical Gas Alarm Athena

Key Features

- Complies fully with all relevent standards

- Support for 1 to 6 individually monitored gases

- Transducer Extender Separate threshold alarms for over and under pressure

- Visual display of current pressure on each monitored gas

- Capable of communicating with a Remote Slave Alarm

- Has the capability of communicating with operating theatre panel or hospital BMS system via computer interface panel

- Has the capability to have transducers mounted in the Zone Service Unit and alarm mounted separately via transducer extender panel.

- Available in surface or flush mounted options

- Only alarm to incorporate end of line monitoring

- No adjustment of pressure switches necessary

- Custom Logos are available subject to minimum order quantities

- Fully tested and certified prior to dispatch

- Available as a stand alone unit or integral with our CENTURION range of Zone Service Units

Standard Specification

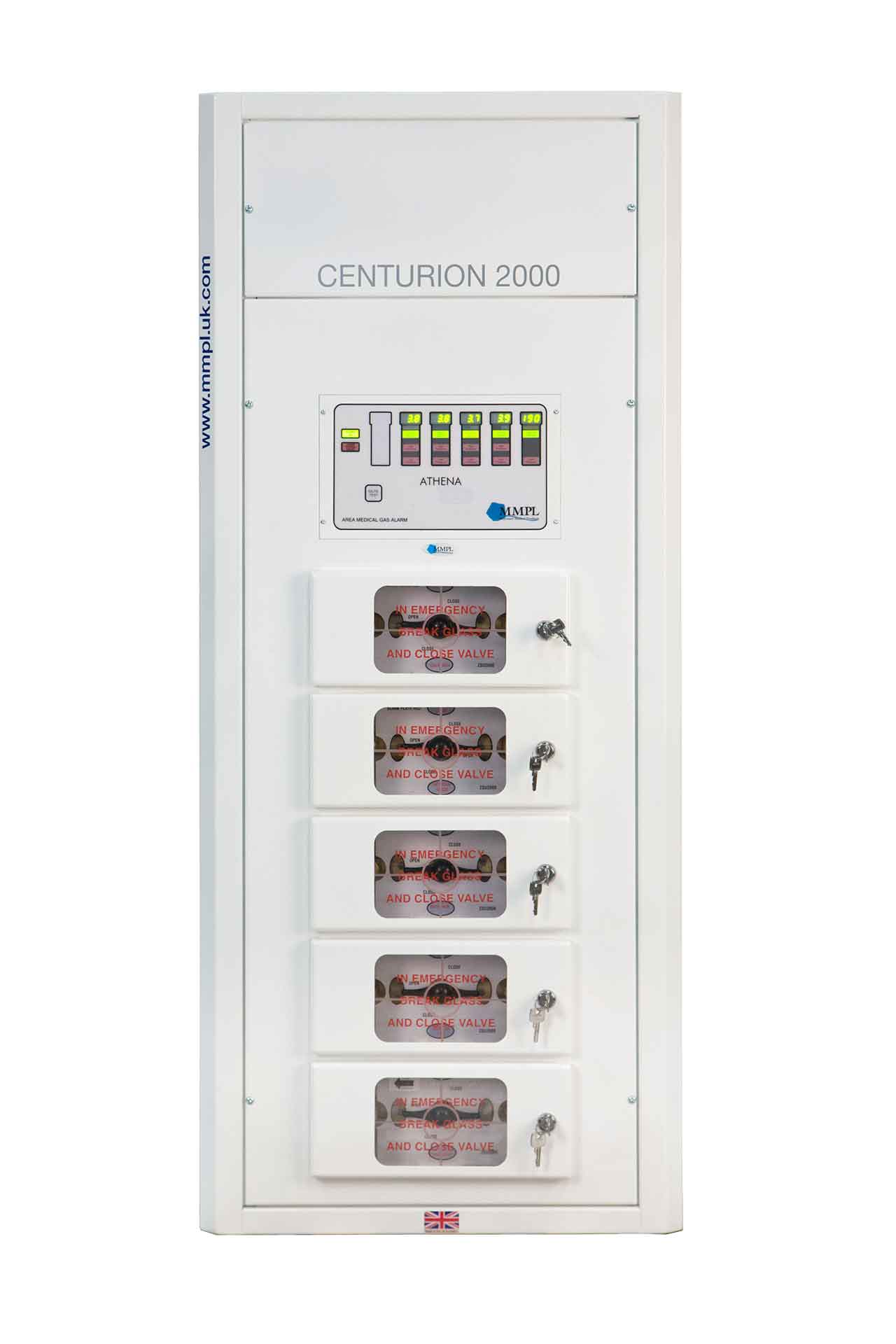

Centurion 2000 ZSU

Key Features

- Fully HTM 02-01 compliant

- Configurable from 1 to 6 gases (including duel systems)

- All valves are fitted with BS 739 NIST connectors

- Can be used with standard pipework sizes from 22 - 42mm

- Available as surface mount or part recessed unit

- Can be supplied without pressure switches or transducers (Departmental)

- Can be supplied with pressure switches or transducers only (for use with remote Alarm Panel)

- Can be supplied complete with alarm

- All makes of Local Alarm Panel can be fitted

- Fully removable front cover for ease of installation and maintenance

- Includes all internal pipework and stubbed external connections for easy installation

- Pressure and electrical tested prior to shipment

Standard Specification

Arcumed Bedhead Trunking

Key Features

- Fully HTM 02-01 compliant

- Configurable from 1 to 6 gases

- Any make of TU can be fitted

- Any type of electrical sockets can be fitted

- Nurse Call, Bed Lights and Angle Poise Lights can be fitted if required

- Electrically pre-wired for ease of installation

- Pre-piped with inert gas soldered medical copper tube

- Fully removable, hinged covers for easy fitting and maintenance

- Pressure and electrical tested prior to shipment

Nightingale Headwall

Key Features

- Fully HTM 02-01 compliant

- Configurable from 1 to 6 gases

- Any make of TU can be fitted

- Can accommodate upto 8 electrical sockets

- Nurse Call, Bed Lights and Angle Poise Lights can be fitted

- Electrically pre-wired for ease of installation

- Pre-piped with inert gas soldered medical copper tube

- Fully removable covers for easy fitting and maintenance

- Pressure and electrical tested prior to shipment

- Each unit can be custom built to exact customer specifications

Mini Pendant

Key Features

- Fully HTM 02-01 compliant

- Sturdy Monocoque design

- Supports up to 4 gas and 4 power outlets

- Mini Pendants are available in different lengths to suit specific requirements

- All gases are equipped with BS 739 NIST hoses for easy installation

- Fully electrically and pressure tested in the factory prior to dispatch

Rigid Pendant

Key Features

- Fully HTM 02-01 compliant

- Sturdy Monocoque design

- Midi Pendants are available in different lengths to suit specific requirements

- Midi Pendant supports upto 9 Gases Supa Midi supports upto 12 Gases

- All gases are equipped with BS 739 NIST hoses for easy installation

- Can support Power Sockets standard and Blue MEIGaN plus Earth Jacks

- Data Sockets, Nurse call, AGSS Remote Control units can be fitted at Customers request

- Fully electrically and pressure tested in the factory prior to dispatch

Retractable Pendant

Key Features

- Fully HTM 02-01 compliant

- Sturdy Monocoque design

- Maxi Pendants are adjustable in length by upto 300mm

- Maxi Pendants are available in different lengths to suit specific requirements

- Can support Power Sockets standard and Blue MEIGaN plus Earth Jacks

- Data Sockets, Nurse call, AGSS Remote Control units can be fitted at Customers request

- Maxi Pendant supports upto 9 Gases Supa Maxi supports upto 12 Gases

- All gases are equipped with BS 739 NIST hoses for easy installation

- Fully electrically and pressure tested in the factory prior to dispatch

Flexi Pendant

Key Features

- Compatible with HTM 02-01

- Pressure tested prior to dispatch

- All connections are fitted with BS 739 NIST hoses for easy installation

- First Fix plate and hex NIST can be supplied before pendant if required

Medical Gas Manifolds

Standard Specification

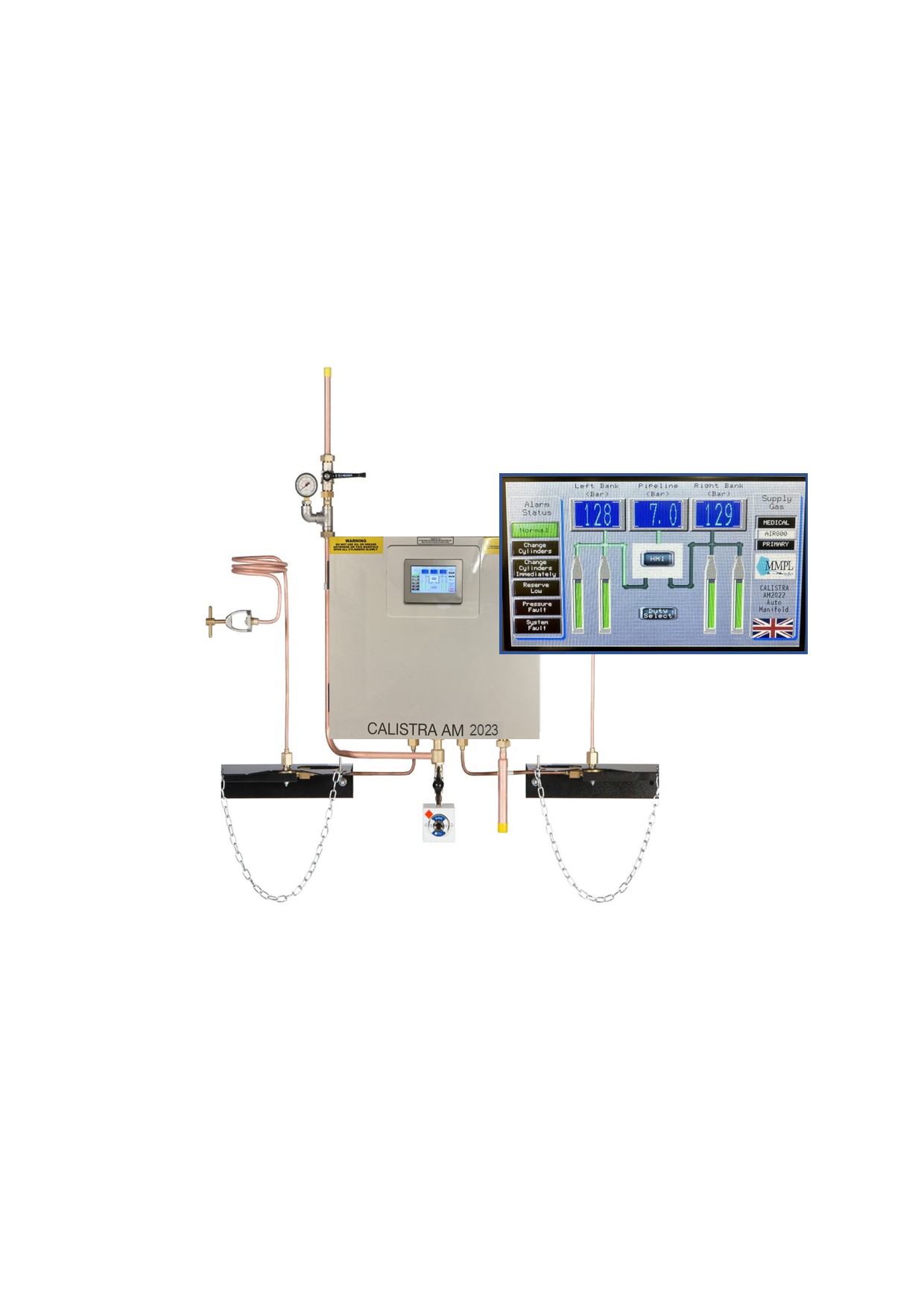

Automatic Manifolds

Key Features

- Fully HTM 2022 / HTM 02-01 compliant

- Fully Automatic Operation

- Fail Safe control system in case of power loss

- Touch Screen HMI Display

- Integral Transmitter

- BMS/Alarm outputs for Remote Status Indication

- Line Fault Monitoring for ERM and ESM backup manifolds wiring

- Available in 400kpa, 700kpa and 1000 kpa output capacities

Standard Specification

All of our Manifolds are built to the highest standards and offer the following specification as standard:

- Complies fully with all relevant standards

- Use two stage regulators for good flow characteristics

- Supplied with pre-set regulators and pressure sensors

- Utilize highly visible readouts for cylinder contents and pipeline pressure

- Tailpipe header blocks have integral non-return valves

- Includes safety relief and isolation valves

- Can be supplied as wall mounted or free standing / floor mounted variants

- Electrical connections are pre-wired to a termination box

- Custom built external cages

Emergency Reserve Manifold (ERM)

Key Features

- Fully HTM 02-01 compliant

- Uses 2 stage regulator for good flow characteristics

- Supplied with pre-set regulators and pressure sensors

- Uses highly visible readouts for cylinder contents and pipeline pressure

- Provides safety relief and isolation valves

- Can be supplied in wall or floor mounted variants

- Electrical connections pre-wired to a termination box

Emergency Standby Manifold (ESM)

Key Features

- Fully HTM2022 compliant

- Uses 2 stage regulator for good flow characteristics

- Supplied with pre-set regulator and pressure switch

- Uses highly visible gauges for cylinder contents and pipeline pressure

- Provided with safety relief valve isolation valve

- Supplied as standard wall mounted or floor mounted option available

- Electrical connections pre-wired to a termination box

Portable ESM Unit

Millennium Medical Products provide a comprehensive range of Manifold systems and accessories that are all hand made at its factory in Greater Manchester.

The Portable ESM unit is designed to safely and rapidly transport two cylinders anywhere in the hospital with the minimum of effort.

Key Features

- Fully HTM 2022 / HTM 02-01 compliant

- Robust steel construction

- Two stage pre-set regulators are used giving good flow characteristics

- Highly visible gauges for cylinder contents and pipeline pressure

- Removable tailpipes for easy transportation

- Gas specific hose connector included

- Fully tested prior to dispatch

Regulators Replacements

Key Features

- Selection is easy, match your Regulator with one of the small photos to obtain the type and Part Number

- The Regulators are Factory set in accordance with the Part Number

- Only Personnel with proper product training should attempt to change Regulators

- No Oil or Grease should be used on Regulators (especially be careful when using hand creams)

- It is not recommended to strip Regulators on site special tools and equipment are used during assembly

- Entonox Regulators should be replaced every two years all other Gases every five years

Tail Pipe Replacements

Key Features

- Fully HTM 2022 / HTM 02-01 compliant

- Cost effecive means of doubling system capacity

Racking

Key Features

- Made to order to customer specifications

- Horizontal and Vertical solutions available

- Hard wearing galvanized finish

- Full range of cylinder types are catered for

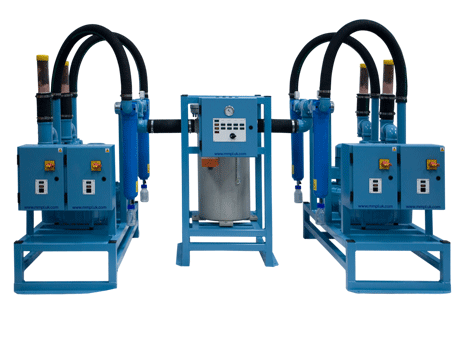

Duplex AGSS Plant

Key Features

- Fully compliant with HTM 02-01

- Tested prior to dispatch

- Single and 3 Phase options

- Stacked systems available

- Anti-vibration mounts fitted to pump units

- Alarm and BMS output connections on all models

- Flexible connections and copper pipeline connections supplies on inlet and exhaust of all units

- Comprehensive Warranty

Options

- GS1001 Remote Control Unit can be supplied as an optional extra

Standard Specification

Simplex AGSS Plant

Key Features

- Fully compliant with HTM 02-01

- Tested prior to dispatch

- Single and 3 Phase option

- Anti-vibration mounts fitted to pump units

- Flexible connections and copper pipeline connections supplies on inlet and exhaust of all units

- Comprehensive Warranty

Options

- GS1001 Remote Control Unit can be supplied as an optional extra

Standard Specification

Air Brake & TU

Millennium Medical Products are proud to be able to supply equipment at all locations within the hospital environment from equipment room, through pipeline to patient delivery on the ward.

We provide a one-stop-shop for all of your needs.

Key Features

- Complies with HTM 02-01

- Supplied with all necessary hoses to connect between the TU, Air Brake and patients mask

- TU is supplied with copper pipeline connector

- Optional extras including wall, rail and machine mounting brackets and patient masks are also available.

External Enclosures

Key Features

- Weatherproof

- Secure

- Durable

- Floor, wall and ceiling mount solutions are available

- Suitable for Simplex and Duplex Systems

- Available as cages or windowed enclosures

- Highly customisable - just ask us what we can do

Options

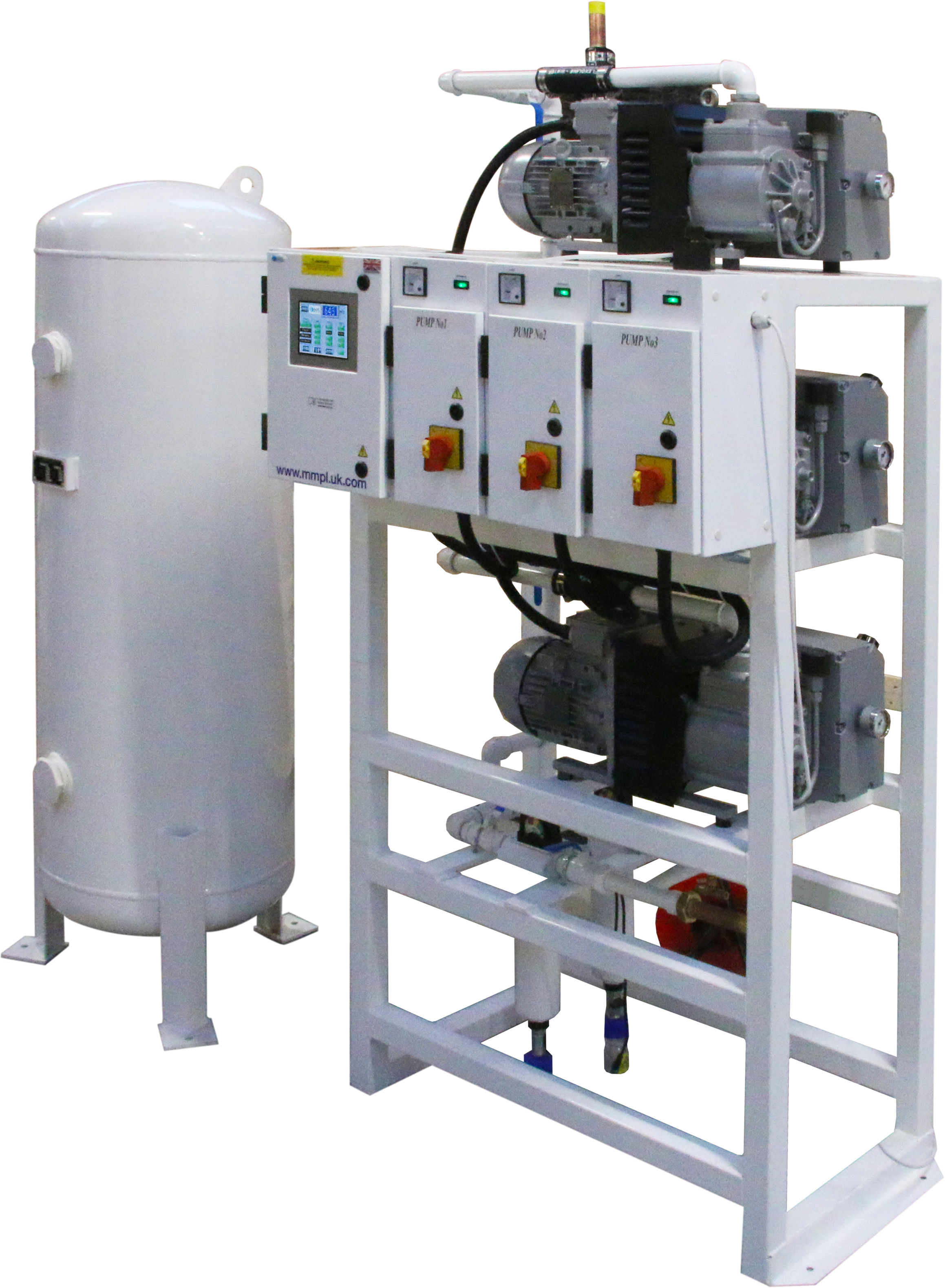

Medical Air Plant Range

- All interconnecting Pipework and wiring are included with each system.

- Flexible connections are provided for all Compressor pipework.

- Anti – vibration mounts are used on all Compressor units to minimize noise and wear.

- “Fail safe” Start up control system in event of power loss.

- Each machine is fitted with adjacent electrical isolator.

- Control panel fitted with HMI display with independent PLC Emergency Back up.

- Alarm and BMS outputs for remote status indication are provided.

- All sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Key Features

- Fully compliant to HTM 02-01 specification

- Flexible connections on compressor pipework

- Fail safe start up control system in the event of power loss

- Alarm and BMS outputs for remote status indication

- Anti vibration mounts on all compressors

- All plants certified and tested before dispatch

Standard Specification

Millennium Medical Products Limited provide a comprehensive range of Medical Air Plant systems and accessories for use throughout the hospital environment.

Like all of our products our Air Plant equipment is designed for reliability and maximum design life whilst being extremely cost effective to buy and requiring minimum maintenance. All MMPL products are hand assembled at our MMPL2 factory located in Hyde, Greater Manchester, UK and carry the EC Declaration of Conformity CE mark.

Hexaplex Medical Air Plant

Standard Specification

All of our Medical Air equipment is built to the highest standards of quality and come as standard with the following features:

Hexaplex Medical Air Plant to HTM02-01 Four Compressor after dryer losses sized to meet the Duty with the other two compressors as first and second standby.

- All interconnecting Pipework and wiring is included with each system.

- Flexible connections are provided for all compressor pipework.

- Anti – vibration mounts are used on all compressors to minimize noise and wear.

- “Fail safe” start up control system in event of power loss.

- (SHFM) Screw Hexaplex Floor Mounted all equipment is mounted on the floor.

- (SHC) Screw Hexaplex Compact compressors mounted on Vessels to reduce space.

- Control panels fitted with highly visible indicators and displays.

- Each compressor is fitted with adjacent electrical Isolator.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Pentaplex Medical Air Plant

Standard Specification

All of our Medical Air equipment is built to the highest standards of quality and come as standard with the following features:

Pentaplex Medical Air Plant to HTM02-01 Three Compressor after dryer losses sized to meet the Duty with the other two compressors as first and second standby.

- All interconnecting Pipework and wiring is included with each system.

- Flexible connections are provided for all compressor pipework.

- Anti – vibration mounts are used on all compressors to minimize noise and wear.

- “Fail safe” start up control system in event of power loss.

- (SPFM) Screw Pentaplex Floor Mounted all equipment is mounted on the floor.

- (SPC) Screw Pentaplex Compact compressors mounted on Vessels to reduce space.

- Control panels fitted with highly visible indicators and displays.

- Each compressor is fitted with adjacent electrical Isolator.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Quadruplex Medical Air Plant

Standard Specification

All of our Medical Air equipment is built to the highest standards of quality and come as standard with the following features:

Quadruplex Medical Air Plant to HTM02-01 Two Compressor after dryer losses sized to meet the Duty with the other two compressors as first and second standby.

Quadruplex Medical Air Plant to HTM2022 Three Compressors after dryer losses sized to meet the Duty with the forth compressor as standby

- All interconnecting Pipework and wiring is included with each system.

- Flexible connections are provided for all compressor pipework.

- Anti – vibration mounts are used on all compressors to minimize noise and wear.

- “Fail safe” start up control system in event of power loss.

- (SQFM) Screw Quadruplex Floor Mounted all equipment is mounted on the floor.

- (SQC) Screw Quadruplex Compact compressors mounted on Vessels to reduce space.

- Control panels fitted with highly visible indicators and displays.

- Each compressor is fitted with adjacent electrical Isolator.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Triplex Medical Air Plant

- All interconnecting Pipework and wiring are included with each system.

- Flexible connections are provided for all compressor pipework.

- Anti – vibration mounts are used on all compressors to minimize noise and wear.

- “Fail safe” start up control system in event of power loss.

- (STFM) Screw Triplex Floor Mounted all equipment is mounted on the floor.

- (STC) Screw Triplex Compact compressors mounted on Vessels to reduce space.

- Control panels fitted with highly visible indicators and displays.

- Each compressor fitted with adjacent electrical Isolator.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Standard Specification

Triplex Medical Air Plant to HTM02-01 each Compressor after dryer losses sized to meet the Duty

Triplex Medical Air Plant to HTM2022 Two Compressors after dryer losses sized to meet the Duty with the 3rd compressor as standby

Duplex Medical Air Plant

- All interconnecting Pipework and wiring are included with each system.

- Flexible connections are provided for all compressor pipework.

- Anti – vibration mounts are used on all compressors to minimize noise and wear.

- “Fail safe” start up control system in event of power loss.

- (SDFM) Screw Duplex Floor Mounted all equipment is mounted on the floor.

- (SDC) Screw Duplex Compact compressors mounted on Vessels to reduce space.

- Control panels fitted with highly visible indicators and displays.

- Each compressor fitted with adjacent electrical Isolator.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Standard Specification

Duplex Medical Air Plant to HTM02-01 and HTM2022 each Compressor after dryer losses sized to meet the Duty

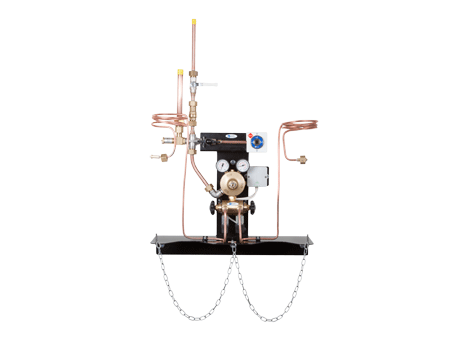

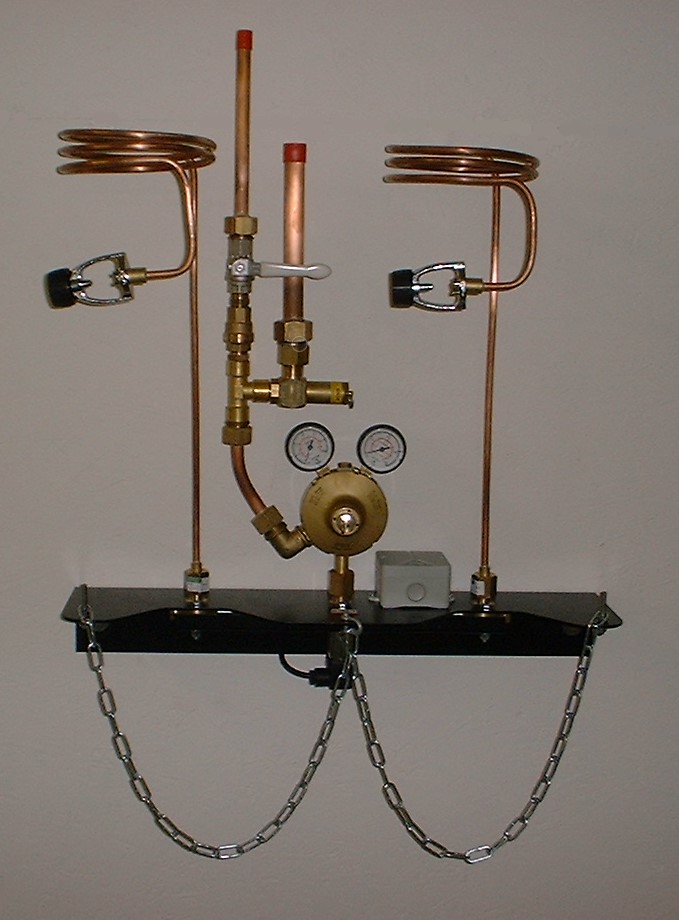

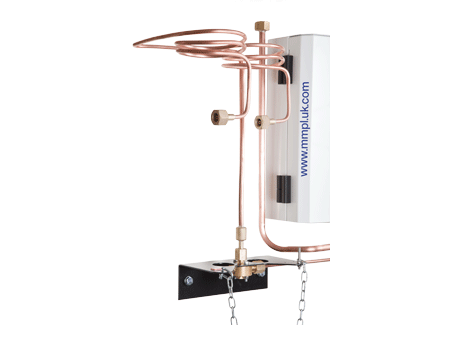

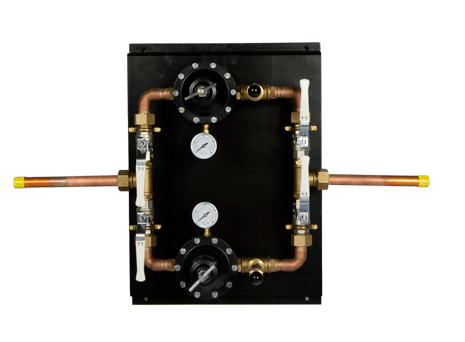

Regulator Stations

Key Features

- Fully compliant to specifications HTM 2022 (No NISTS) and HTM 02-01 (NISTS fitted)

- Simplex for surgical Air and Duplex for Medical Air are available

- Flat faced 'o' ring pipeline unions for easy installation and maintenance

- Includes gauges and pressure relief valves

- Standard Atmospheric discharge pressure relief valves for Medical Air

- For other gases Piped discharge pressure relief valves are available at an extra cost

- Pre set and pressure tested in the factory prior to dispatch

Air Treatment Accessories

Key Features

- Conforms to the Water Resources Act 1991

- Works with Float, level and pneumatic drains

- Four 1/2" inlet ports

- Settling and Flotation Chamber

- Oil-Collection Vessel with Over Flow safeguard

- Test-Set with Check Glass and oil test

Medical Vacuum Plant Range

- All interconnecting Pipework and wiring are included with each system.

- Flexible connections are provided for all pump pipework.

- Anti – vibration mounts are used on all pump units to minimize noise and wear.

- “Fail safe” Start up control system in event of power loss.

- Each machine is fitted with adjacent electrical isolator.

- Control panel fitted with HMI display with independent PLC Emergency Back up.

- Alarm and BMS outputs for remote status indication are provided.

- All sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Standard Specification

Hexaplex Medical Vacuum Plant

Standard Specification

All of our Vacuum equipment is built to the highest standards of quality and come as standard with the following features:

Hexaplex Vacuum Plant to HTM02-01 Four Pumps sized to meet the Duty with the 5th and 6th pump as 1st and 2nd standby

- All interconnecting Pipework and wiring is included with each system.

- Flexible connections are provided for all pump pipework.

- Anti – vibration mounts are used on all pump units to minimize noise and wear.

- “Fail safe” Start up control system in event of power loss.

- Each machine is fitted with adjacent electrical isolator.

- Control panel fitted with highly visible indicators and display.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Pentaplex Medical Vacuum Plant

Standard Specification

All of our Vacuum equipment is built to the highest standards of quality and come as standard with the following features:

Pentaplex Vacuum Plant to HTM02-01 Three Pumps sized to meet the Duty with the 4th and 5th pump as 1st and 2nd standby

- All interconnecting Pipework and wiring is included with each system.

- Flexible connections are provided for all pump pipework.

- Anti – vibration mounts are used on all pump units to minimize noise and wear.

- “Fail safe” Start up control system in event of power loss.

- Each machine is fitted with adjacent electrical isolator.

- Control panel fitted with highly visible indicators and display.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Quadruplex Vacuum Plant

Standard Specification

All of our Vacuum equipment is built to the highest standards of quality and come as standard with the following features:

Quadruplex Vacuum Plant to HTM02-01 Two Pump sized to meet the Duty with the 3rd and 4th pump as 1st and 2nd standby

Quadruplex Vacuum Plant to HTM2022 Three Pumps sized to meet the Duty with the 4th pump as standby

- All interconnecting Pipework and wiring is included with each system.

- Flexible connections are provided for all pump pipework.

- Anti – vibration mounts are used on all pump units to minimize noise and wear.

- “Fail safe” Start up control system in event of power loss.

- Each machine is fitted with adjacent electrical isolator.

- Control panel fitted with highly visible indicators and display.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

Triplex Vacuum Plant

Standard Specification

All of our Vacuum equipment is built to the highest standards of quality and come as standard with the following features:

Triplex Vacuum Plant to HTM02-01 each Pump sized to meet the Duty

Triplex Vacuum Plant to HTM2022 Two Pumps sized to meet the Duty with the 3rd pump as standby

- All interconnecting Pipework and wiring is included with each system.

- Flexible connections are provided for all pump pipework.

- Anti – vibration mounts are used on all pump units to minimize noise and wear.

- “Fail safe” Start up control system in event of power loss.

- Each machine is fitted with adjacent electrical isolator.

- Control panel fitted with highly visible indicators and display.

- Alarm and BMS outputs for remote status indication are provided.

- All pressure switches and sensors are factory set for ease of installation.

- All plants are fully tested and certified before being despatched.

- Each plant is covered by a full warranty.

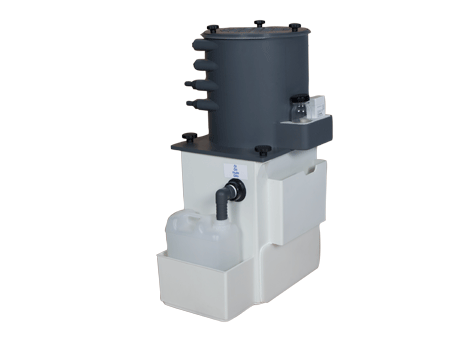

Dental Vacuum Plant

Key Features

- Fully HTM 2022 compliant

- Simplex, Duplex, Triplex and Quadruplex solutions

- Alarm and BMS outputs for remote status indication are provided

- Anti-vibration mounts are fitted to all pump units to minimise noise and wear

- Optionally available with power efficient VSD Pump units to reduce operational costs.

- Pressure sensors and switches are pre-set at the factory for ease of installation

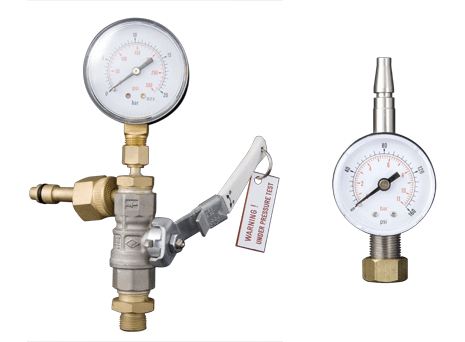

Test Units

Key Features

- Full range of TU and NIST test units are available

- Uses include Pressure Testing, Purging and Gas Feeding

- Analogue gauges supplied as standard (Digital option available)

- Fitted with tamper proof locking device

- 3/8" cone seat for connection to gas source

Digital Gauge - Option

Millennium Medical Products provide a comprehensive range of Test Equpiment for all aspects of installation and maintenance activities.

Digital Gauges can be supplied as an option to all of our test units.

Key Features

- Pressure reading is accurate to within 0.1% at temperatures within the range 0 - 50 degrees centigrade

- Pressure updates twice a second giving an immediate indication of leaks

- Reduces test time for pipeline pressure testing as leaks are immediately visible

- Standard working range - 1 to 30 bar

Anti Confusion Probes

Key Features

- Full range of TU and NIST anti confusion probes are available

- Uses include checking the operation of terminal units and non-interchangability checking for gas specificy

Hoses and Tapes

Key Features

Hose:

- Carbon Core ensures that Static build up does not harm sensitive equipment

- Many sizes / colours available

Tape :

- Full range of Medical and Laboratory tapes are available

- All tapes conform to relevant standards HTM 02-01, BS 1710, BS4800 and BS 5252 as appropriate

- Medical tapes are 150mm wide

- Laboratory tapes are 50mm wide

Flow Meters

Key Features

- Robust construction

- Anodized aluminium body

- Poly-carbonate inner and outer tube

- Calibrated to operate at 4 Bar

- Oxygen Hi-Flow 0-15 L/M or Lo-Flow 0.15-4.5 L/M available

- Med Air Hi-Flow 0-15 L/M or Lo-Flow 0.15-4.5 L/M available

- Available with Fixed BS Probe or 3/8" BSP connector

Options

- Humidifiers Disposable or Autoclave clean available

- Face Masks Adult and Pediatric available

- Nasal Cannula available

Suction Controllers

Mobile High Vacuum Suction Units

Key Features

- Suction Controller

- Disposable Bacterial Filter

- Safety Overflow Valve

- Two or Four Autoclave Clean Jars options available

- Each Jar 1800ml capacity

- Robust Construction

- Five Wheeled Stand for Extra Stability

Electric High Vacuum Suction Units

Key Features

- Electric High Vacuum Suction Units can be transported easily.

- Easy vacuum regulation making the Units ideal for bedside use.

- Low noise emission reduces disturbance in the operation room or at the patient’s bedside

- Rapid vacuum build up and allows precise regulation.

- Portable and Mobile Units Flow rate 26 l/m with a maximum Vacuum of 625mmHg

- Theatre Units Flow rate 45 l/m with a maximum Vacuum of 630mmHg

- Double Jar version has change over valve to allow operator to switch jars without interrupting suction

- Safety overflow valves and Disposable Bacterial Filters fitted as standard

Options

- Standard Units require 230V AC power supply other voltages available by request

- Available with single or double 1800ml Autoclave clean Jars

- Hydrophobic Filters can be fitted on request

Medical Copper Tubing

MMPL medical grade copper tube are pipeline solutions for medical installations. Degreased copper tubes and fittings are to relevant standards and are kite marked. The medical tubes are specifically designed for copper medical gas and vacuum systems. Medical copper tubes and medical fittings are suitable for all gas types

Medical grade degreased copper tube BS - Size range and details

| Diameter (mm) | Thickness (mm) | Length (m) |

|---|---|---|

| 12 | 0.6 | 6 |

| 15 | 0.7 | 3&6 |

| 22 | 0.9 | 3&6 |

| 28 | 0.9 | 3&6 |

| 35 | 1.0 | 6 |

| 42 | 1.0 | 6 |

| 54 | 1.0 | 6 |

| 67 | 1.2 | 6 |

| 76 | 1.5 | 6 |

| 108 | 1.5 | 6 |

| 133 | 1.5 | 6 |

| 159 | 2.0 | 6 |

| 219 | 3.0 | 6 |

Medical Copper Fittings

MMPL medical grade copper tube are pipeline solutions for medical installations. Degreased copper tubes and fittings are to relevant standards and are kite marked. The medical tubes are specifically designed for copper medical gas and vacuum systems. Medical copper tubes and medical fittings are suitable for all gas types

Medical grade degreased copper tube BS - Size range and details

| Diameter (mm) | Thickness (mm) | Length (m) |

|---|---|---|

| 12 | 0.6 | 6 |

| 15 | 0.7 | 3&6 |

| 22 | 0.9 | 3&6 |

| 28 | 0.9 | 3&6 |

| 35 | 1.0 | 6 |

| 42 | 1.0 | 6 |

| 54 | 1.0 | 6 |

| 67 | 1.2 | 6 |

| 76 | 1.5 | 6 |

| 108 | 1.5 | 6 |

| 133 | 1.5 | 6 |

| 159 | 2.0 | 6 |

| 219 | 3.0 | 6 |

Containerized Medical Gas Plantrooms

Key Features

- We can supply and fit equipment only

- We can supply and fit equipment including Pipework and Electrics

- As above with Air Conditioning for heating or cooling

- Choice of Colours